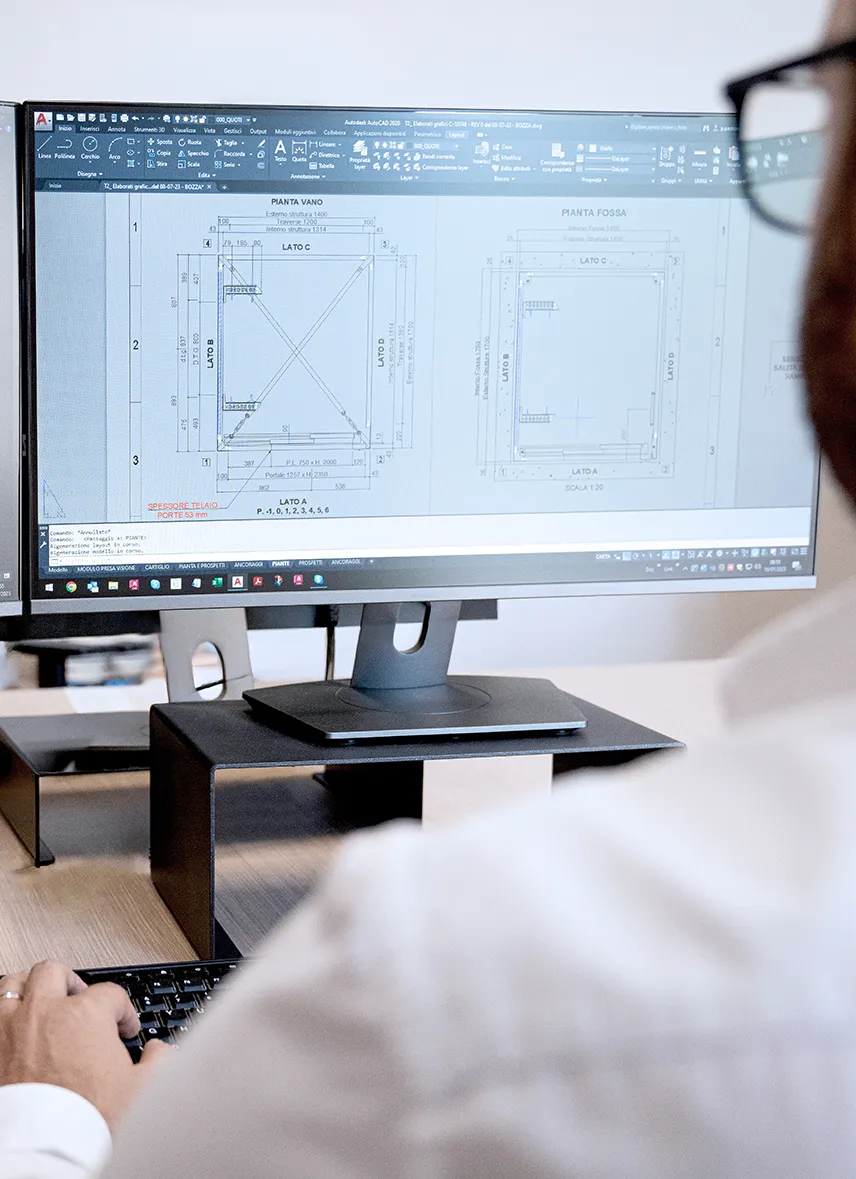

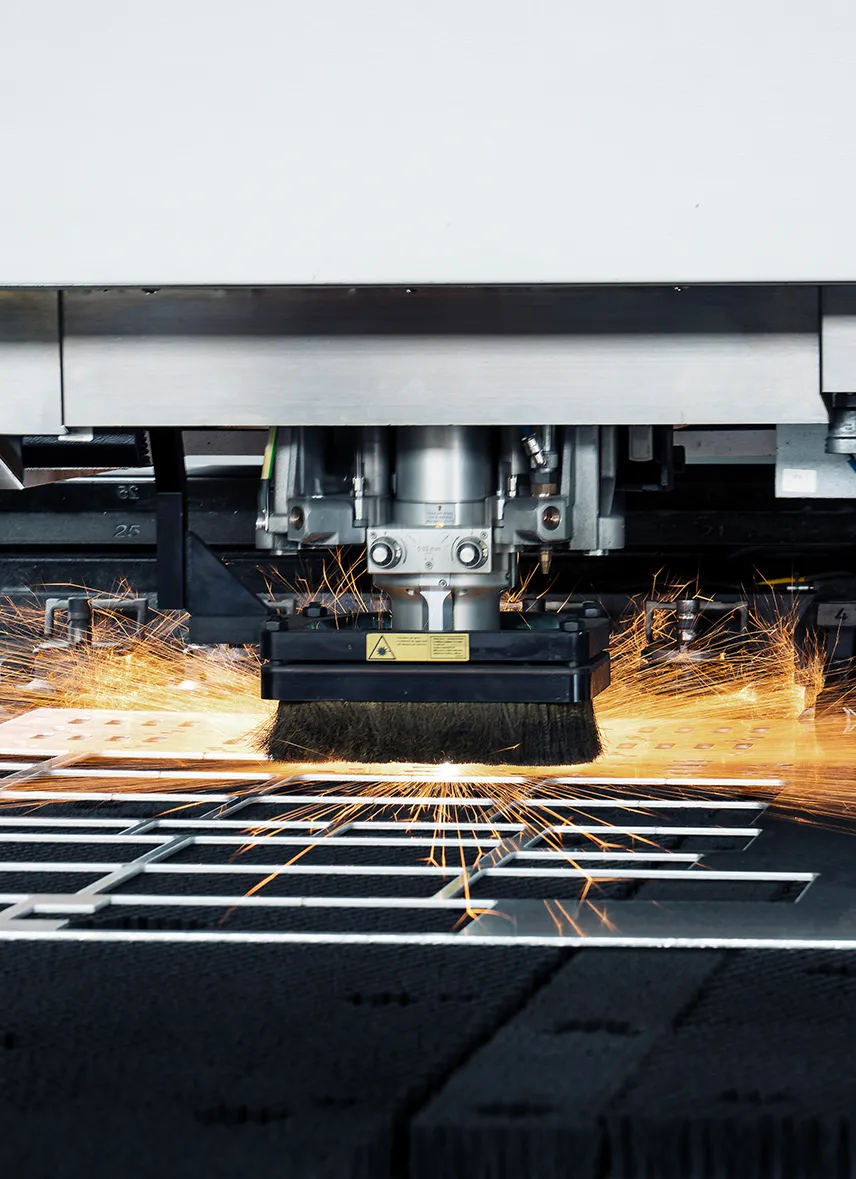

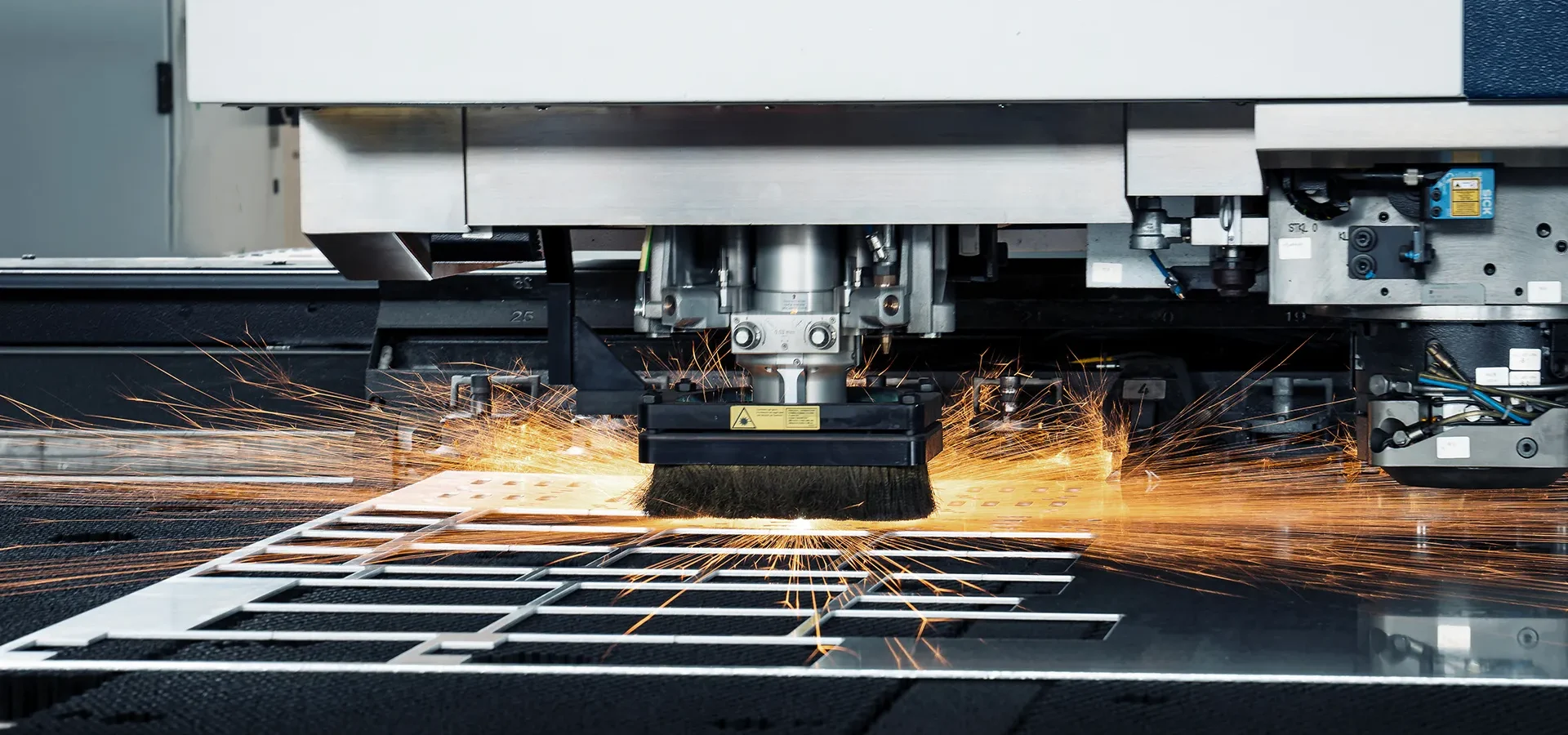

Every machine is managed by specialized operators who are constantly trained to ensure maximum efficiency in every phase. The combination of advanced technology and human expertise allows TEKNO SMS to create customized systems with high-quality standards within competitive timeframes.